Case Studies

Revolutionizing Automotive Domain: The Two-Wheeler Electric Vehicles Revolution – Powering Ahead with Cutting-Edge Mechanical Parts

DESIGN

Case Study 1: Improving Frame Body Quality for Electric Vehicles

Challenge: A leading manufacturer of electric vehicles faced a quality control issue with frame body components, leading to high rejection rates and scrap losses.

Solution: Adhithya Innovations conducted a thorough analysis and implemented process improvements, resulting in:

Key Outcomes:

- Significant cost savings

- Zero scrap value

- Zero-line stoppage

- Improved quality

PRODUCT DEVELOPMENT

SUPPLIER SELECTION

SUPPLIER QUALIFICATION

Case Study 2: Reducing Battery Pack Rejection in Electric Vehicles

Background: A leading Electric Vehicle (EV) manufacturer aimed to improve the quality of their battery packs, Plastic Enclosures and reduce rejection rates.

Challenge: The company faced a battery pack rejection rate of 4%, resulting in significant costs and production delays.

Solution: Adhithya Innovations partnered with the company to implement a comprehensive quality control program, which included:

- Manufacturing Process Audits, Supplier Selection and Supplier Qualification

- Improved testing procedures

- Revised supplier quality standards

- Employee training and awareness programs

Results:

- Battery pack rejection rate reduced from 4% to 1%

- Significant cost savings

- Improved production efficiency

- Enhanced product quality and reliability

PRE-PRODUCTION VALIDATION

PRODUCTION PLANNING

INCOMING QUALITY CONTROL

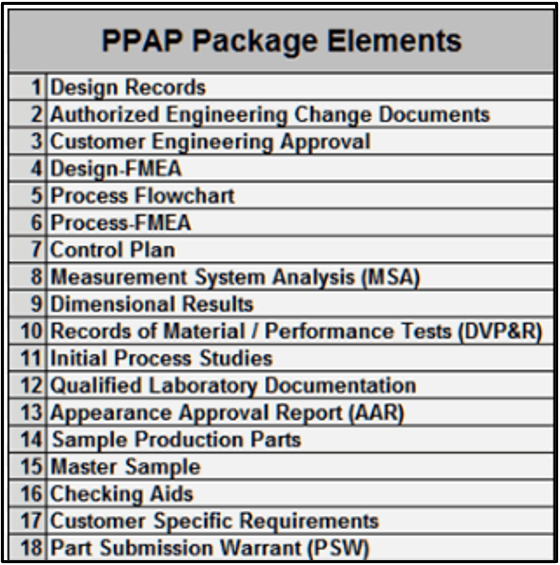

Case Study 3: PPAP for Electric Vehicle Batteries

Background: Leading EV manufacturer needed a PPAP for battery packs to ensure quality and reliability.

Challenge: Implementing a comprehensive PPAP meeting international standards and customer requirements.

Solution: Adhithya Innovations collaborated to develop and implement a customized PPAP, including:

- Design and development reviews

- Prototype testing and validation

- Pre-production validation (PPV)

- Process capability studies

- Initial process capability approval

- Qualified laboratory and testing facilities

- Continuous monitoring and control

Results:

- Successful PPAP implementation for electric vehicle batteries

- Ensured compliance with international standards and customer requirements

- Improved quality and reliability of battery packs

- Enhanced customer satisfaction and trust

- Reduced production costs and improved efficiency

PRODUCTION AND ASSEMBLY

Case Study 4: Production & Assembly in EVs

Challenge: Inefficient production & assembly processes in electric vehicle manufacturing.

Solution: Adhithya Innovations analyzed & optimized workflows, implemented lean techniques, automated assembly lines, enhanced quality control & trained personnel.

Results:

- 30% reduced production time

- 25% lower labor costs

- 20% improved product quality

Best Practices: Continuously analyze & optimize processes, leverage automation & technology, enhance quality control & train personnel.

PACKAGING

SHIPPING

Case Study 5: Packing & Shipping in EVs

Challenge: Inefficient processes damaged EV components, caused delays, and increased costs.

Solution: Customized packing, automation, optimized routes, and real-time tracking.

Results:

- 40% less damage

- 25% faster delivery

- 15% lower costs

- Happier customers

Transforming the Aerospace Industry: A Revolution in Customer Experience

-

Incident Reporting: Easy submission of safety incident reports by aviation professionals

-

Data Management: Analysis of reported incidents

-

Data Analytics: Identification of trends, patterns, and insights to inform safety improvements

-

Stakeholder Engagement: Automated notifications and reports to relevant authorities, airlines, and other stakeholders

-

Enhanced Safety: Improved incident reporting and analysis, leading to proactive safety measures

-

Increased Efficiency: Streamlined reporting process, reducing manual errors and time

-

Data-Driven Insights: Actionable intelligence and industry stakeholders to inform safety decisions

-

Compliance: Adherence to international safety reporting standards and regulations

-

Increased reporting rates

-

Improved data quality

-

Enhanced safety awareness

-

Data driven decision making

- Identify key variables contributing to flight delays from a large dataset.

- Our team applied Principal Component Analysis (PCA) to simplify the complex data set and determine the most significant factors causing flight delays.

- By pinpointing the crucial variables, our client can now implement targeted improvements to minimize delays and enhance overall flight operations.

Focus on Bathroom Automation (Mechanical Design) – Adhithya Innovations As Catalyst For a Cleaner & Healthier World

Case Study 1: Complete Concept to Production (Mechanical Design) – Bathroom Automation – Revolutionizing Commode Servicing (Automatic Flushing System)

Problem Statement

- Inefficient commode servicing processes, requiring complete removal and manual intervention, leading to increased downtime and maintenance costs.

Solution Overview

- Design and integration of a modular front enclosure, enabling swift access, repair, and replacement of internal components, minimizing labor requirements and enhancing overall hygiene.

Key Benefits

- Reduced Mean Time To Repair (MTTR)

- Improved First-Time Fix Rate (FTFR)

- Enhanced Customer Experience (CX)

- Increased Operational Efficiency (OE)

Implementation Roadmap

- Design For Manufacturability (DFM): Collaborative design and prototyping

- Verification and Validation (V&V): Rigorous testing and quality assurance

- Integration and Installation: Seamless deployment and commissioning

- Training and Support: Comprehensive maintenance and troubleshooting guidance

Conclusion

- Streamline bathroom automation servicing with a modular front enclosure, driving efficiency, productivity, and customer satisfaction.

Case Study 2: Value Engineering in Electronic Flushing System

Challenge

- Complex design with many components

- High material costs due to excessive weight

Solution

- Simplified component architecture

- Minimized part weight through material optimization

Results

- 30% fewer components

- 25% weight reduction

- 20% cost savings

Methodology

- Functional analysis

- Design optimization

- Material selection

- DFMA implementation

Conclusion

- Value engineering optimized the electronic flushing system, reducing complexity, weight, and costs while maintaining performance.